SH SHCM m 492 ft and above. Dense Phase Pneumatic Conveying is a method for moving difficult abrasive or friable materials at slow speed.

Ship Motions The Ultimate Guide In 2020 Boat Stuff Motion Ship

Concrete block stone brick for exterior walls or walkways.

Building a vessel to transport dense material. You must have a current copy in your possession before you can legally ship special form radioactive materials. The low velocity of dense phase conveying allows for less wear and tear on both the system and the materials being conveyed thereby minimising maintenance. Alumina and fly ash are two common materials that can come in a.

The basic system provides an economical option for dense phase pressure vessel conveying. It pushes material along an enclosed pipe in a plug form using small amounts of gas at a low velocity but high pressure. Please note that these certificates have expiration dates.

Maritime transport or ocean transport and fluvial transport or more generally waterborne transport is the transport of people or goods via waterways. Lumber plywood SIPs windows roofing. The Cementveyor is a single vessel dense phase transporter.

Aluminum foil Ruler Tape Calculator Scrap piece of paper and pen or pencil Bucket tub sink or dishpan Water Pennies. Freight transport by sea has been widely used throughout recorded historyThe advent of aviation has diminished the importance of sea travel for passengers though it is still popular for short trips and pleasure cruises. We have developed many fi rsts in the industry such as our dense.

You may need as many as 200 depending on the size and shape of the boats you make. These materials benefit from a smooth moving material stream. Secure construction materials to the pallet with wrap and ties.

Some of the materials to be transported may be capable of being conveyed in dense phase and hence at low velocity while others may have no dense phase capability and will have to be conveyed in dilute phase with a high conveying air velocity. The low density of aluminum combined with high strength toughness and corrosion resistance allow vessel designers to achieve weight savings of 15-20 over steel or composite designs. An example of a special form certificate is shown in Appendix G.

The second category high pressure systems are known as dense phase systems. Certificate for at least one year after the latest shipment of special form radioactive material 173476a. Bulk granular materials our 16 conveying concepts are state of the art.

However larger transport vessels such as cargo container ships and naval warships are still built primarily of metal Fig. These systems utilize air pressure above 15 psig up to 50 psig in the pipe and use positive pressure to push materials through the conveying line at relatively low velocities from 100 fpm to a maximum of 1000 fpm much like extruding. The Coperion K-Tron Omniveyor TM basic pressure vessel system provides manual single point control of convey air pressure and air flow along the entire length of the convey line utilizing Coperion K-Trons air injectors.

As used in the Guide the term asphalt solutions refers to asphalt solutions listed in Appendix I to Annex. Velocities are below the saltation level the critical velocity at which particles fall from suspension in the pipe. Take care not to exceed the dimensions of the pallet or stack it too high.

Consider using polybags and canvas to secure loose bricks and bags together. Place heavier items towards the bottom smaller lighter items towards the top. FreightCenter is your go-to resource for delivering new home construction materials to the right place at the right time including the following types of cargo.

Weight savings equate to higher speed increasingly demanded for vessels such as ferries patrol boats military. With over 40 years of building highly effi cient dense phase and dilute phase pneumatic conveying systems you can be assured that Dynamic Air technology is the latest and the best in the industry. The conveying performance of different grades of the same material can also differ widely.

The system is designed to produce high material-to-air-ratios and low conveying velocities for cement conveying. Rag or paper towels Dry rice and measuring cup optional Preparation Cut. Dense Phase Omniveyor Basic Flyer.

Dense phase conveying systems have a low air-to-material ratio. Modern building materials such as fiberglass and high-quality plastics provide both strength and low-density materials for smaller vessels like racing boats canoes and kayaks. Dense phase systems therefore move the material through the piping in batches with discrete dunes or plugs of material separated by pockets of air.

In addition the classification notation is to be assigned to vessels having lengths of 150. Abrasive bulk materials can damage your equipment if moved at higher velocities where they rub against the interior of the pipe especially at the bends. Pressure vessel dense phase conveying is ideal for moving granular and powdery materials such as fly ash alumina cement and gypsum.

A Except as provided in paragraphs b through f of this section hazardous materials authorized to be transported by vessel may be carried on board a vessel in a transport vehicle or freight container subject to the following conditions see additional requirements concerning the transport of Class 1 explosive materials in 176168 through 176172 of this subchapter. DH36 shipbuilding steel plate is used for shipbuilingplatformThe shipbuilding steel plate grade DH36 is the high tensile strength steelDH36 shipbuilding steel is the Hull structural steelwith its good toughness properties higher strengthstrong corrosion-resistancethe processing propertiesand welding propertiesASTM A131 DH36 steel plate can be used in the manufacture of the ships hull structure. Rules for Building and Classing Steel Vessels Steel Vessel Rules.

The Cementveyor comprises a small pressure vessel fitted with the unique Macawber Dome Valve for vessel filling.

Stem Engineering Design Challenge 4 Design A Cargo Ship Engineering Design Challenge Stem Engineering Engineering Design

Blame For Beirut Explosion Begins With A Leaky Troubled Ship The New York Times

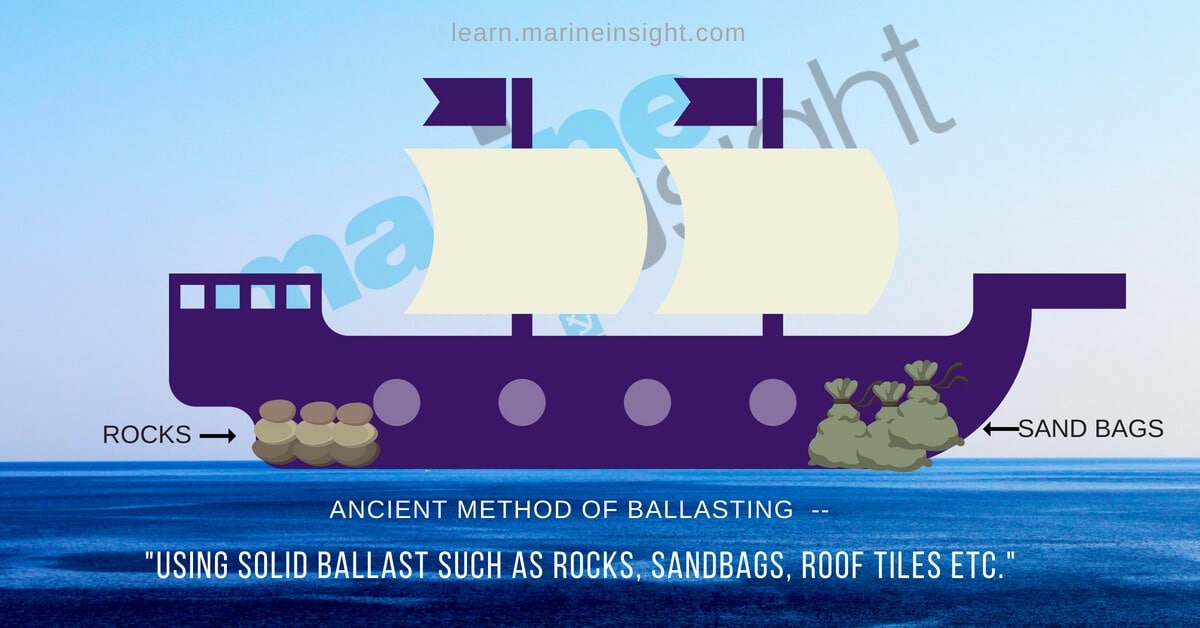

A Guide To Ballast Tanks On Ships

Dry Dock Types Of Dry Docks Requirements For Dry Dock

10 Ship Terms And Definitions Even Smart People Misuse

Protecting Ships And Trawlers From Corrosion Metallisation Ltd

Evergreen G Class Container Ship Wikipedia

Ancient Ship Galera Templates Vector Free Download Ship Vector Sailing Ships Ancient

Ever Given A Massive Cargo Ship Is Still Stuck In The Suez Canal

How Did A Ship Get Stuck In The Suez Canal And What Happened Afterward The Washington Post

Different Types Of Barges Used In The Shipping World

7 Of The Most Impressive Icebreaker Ships Ie

How Much Does It Cost To Fuel A Cargo Ship Quora

Cargo Boat Steam Challenge Steam Challenges Engineering Challenge Steam Activities

How Are Ships Made An Overview More Than Shipping

Calculating Forces On Deck Cargo Of Ship A Simplified Approach

How Do Ships Float On Water Transportation Theme Transportation For Kids Matter Science

Comments

Post a Comment